OUR PRINCIPLES

- Simplify – We believe in simple and powerful solutions and Optel is designed to provide such solutions to our customers. Optel is designed to support a lean manufacturing environment.

- Integrate – Optel is database driven with over 300 database tables that model and integrate all functions in an electronics manufacturing shop floor. Data integration is essential to be able to control and measure processes and react to unexpected disturbances.

- Measure – To be able to control a manufacturing system, we need to be able to measure its performance. Optel provides real time measurements of plant, line, and machine performance and downtime reasons and times.

- Control – From dynamic production scheduling, machine optimization and programming and real time communication with all types of equipment, Optel controls process execution and prevents defect or incomplete products to be shipped to the customer.

- Optimize – Optel includes state of the art optimization algorithms to optimize production and maximize the throughput.

OUR SOLUTIONS

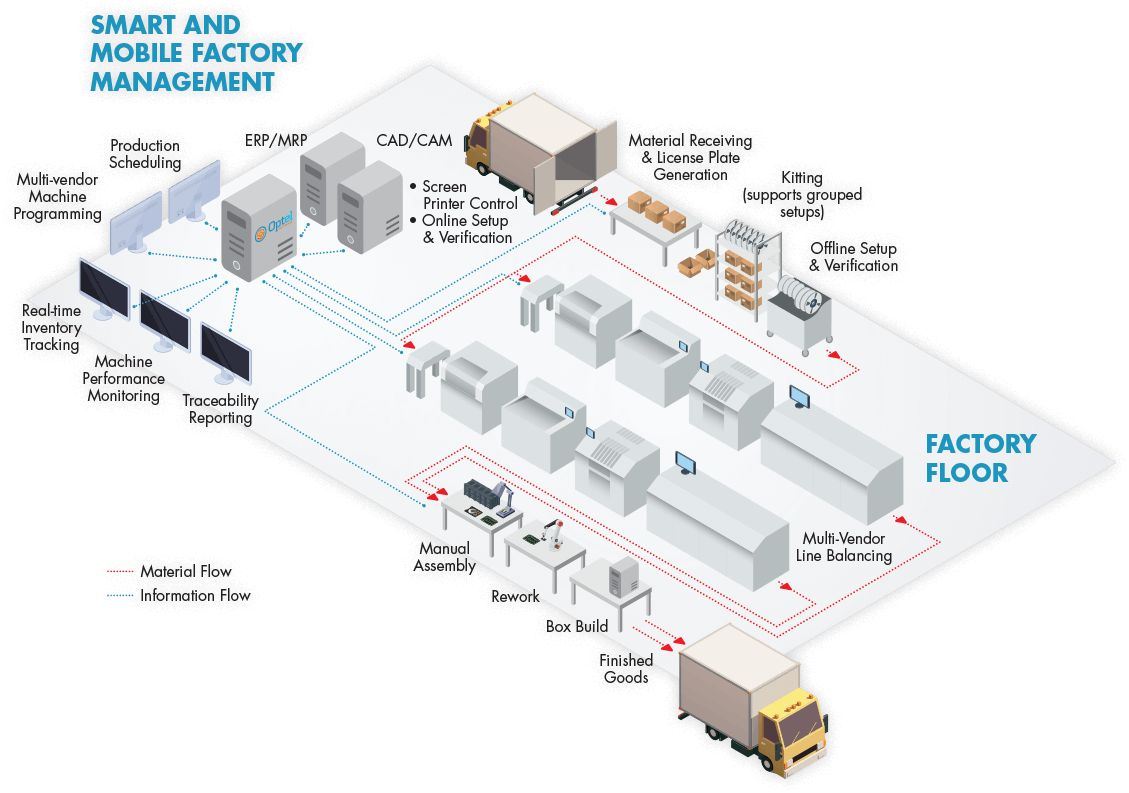

Optimal Electronics’ Optel MES solution begins where ERP/MRP ends — providing the ability to integrate and communicate with production equipment, and interface in a standard way to your company’s ERP/MRP, other MES, and reporting systems. Optel is designed to work with your ERP/MRP systems to enable the seamless sharing of information and improved shop floor control. The specific information that is exchanged depends on the Optel modules implemented.

Optel is the most comprehensive and powerful software system for managing the PCB manufacturing process. It implements Lean Manufacturing best practices, resulting in increased agility, throughput and quality, while reducing costs and setup times. This state-of-the-art system comprises a full suite of modules all integrated by a single global database.