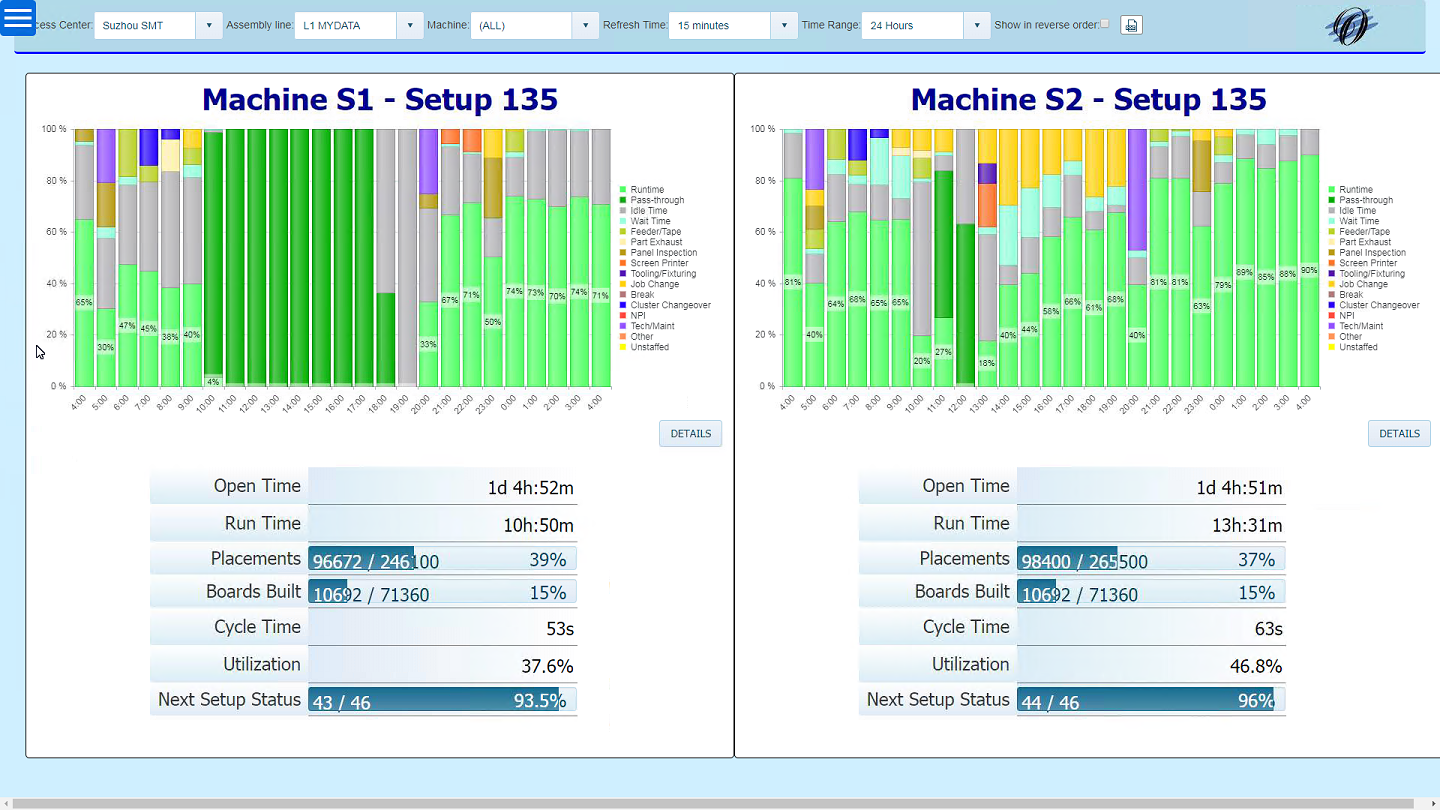

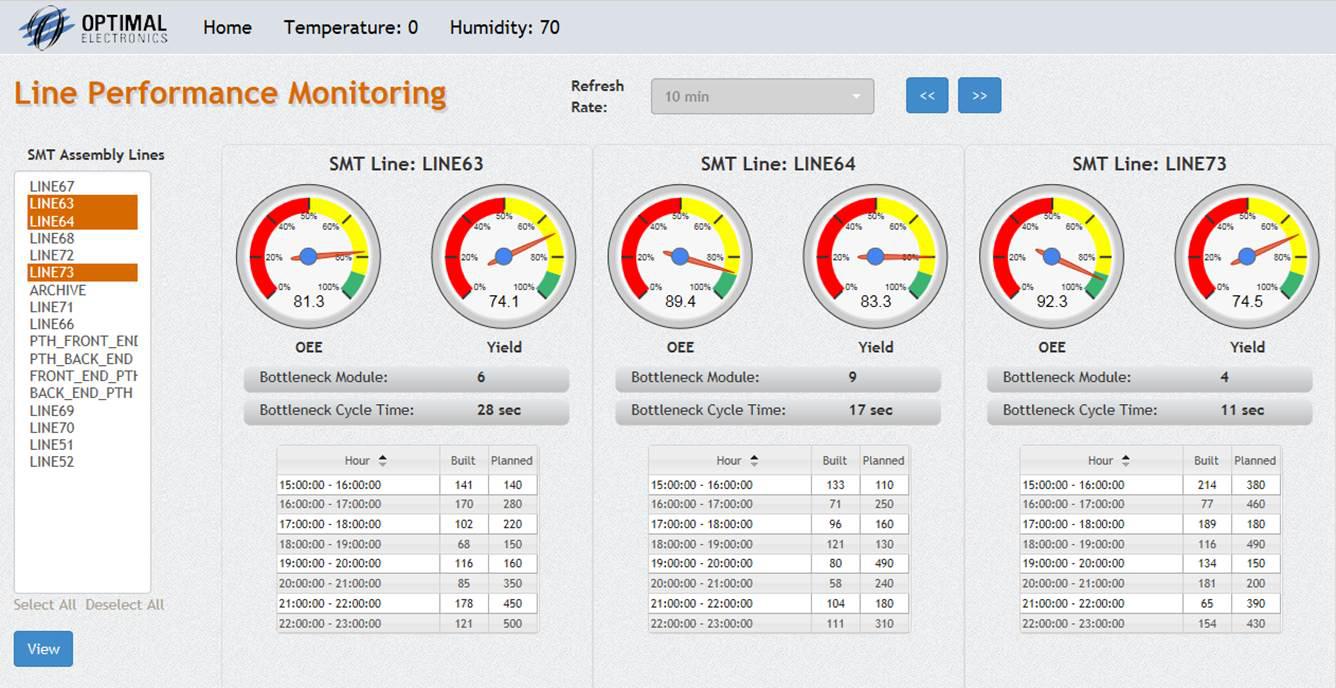

Optel provides real time performance monitoring. For example, performance of every pick and place machines is monitored in real time by hour, shift, day, month, etc. Machine run time, setup time, and down times are captured and displayed. In addition, current job status and next kit status are also monitored. Downtimes are captures including reasons for downtime. Downtime Pareto charts can be displayed.