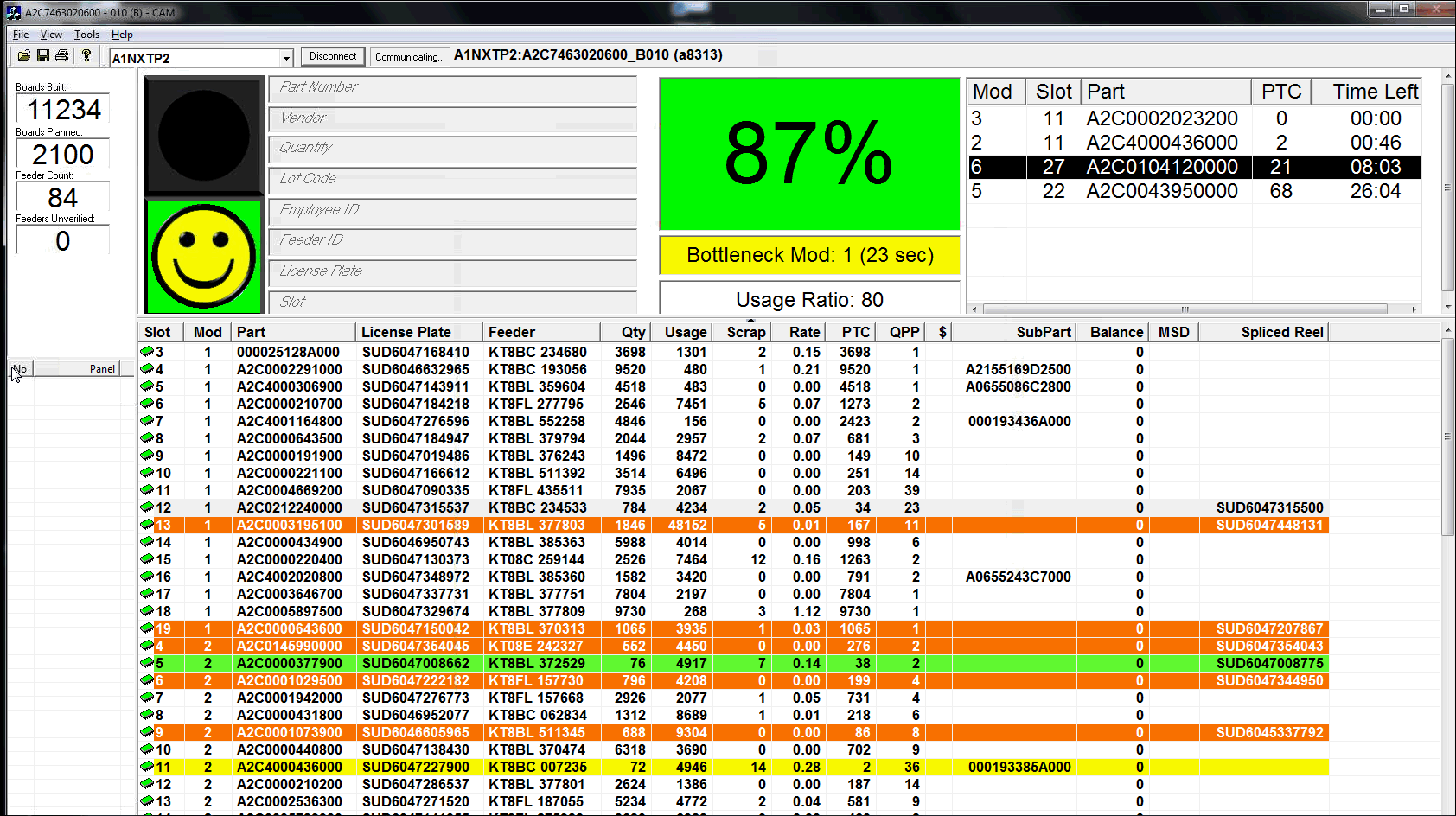

Optel provides comprehensive capabilities for accurate work order, panel, and reference designator level component traceability for SMT pick and place, manual insertion, box build, rework, and die attach assembly operations. Optel interfaces in real time with SMT placement machines on the production line and enables online setup verification to be fully automated, ensuring that the correct parts are loaded into the correct SMT machine slots. With the Optel system, your manufacturing operation can also leverage automated capabilities for real-time component cycle counting and advanced parts outage warnings to significantly reduce machine downtime and increase production output. Optel employs the Chain of Custody approach that refers to the concept of maintaining a history of an item’s past. Chain of Custody is used extensively in the Medical field to manage patient records and manufacturing is used to maintain a record of components used to assemble a product Traceability requires that Chain of Custody is maintained on all affected materials and processes.