In manufacturing, lots of moving pieces come together to create complex electronics. From circuit board printing to the final assembly, the supply chain and manufacturing processes can be long and complex.

Managing everything from raw materials to the workforce can be challenging, but Manufacturing Execution Systems (MES) can help decision makers better organize their electronics manufacturing processes. So, what is MES?

MES Defined

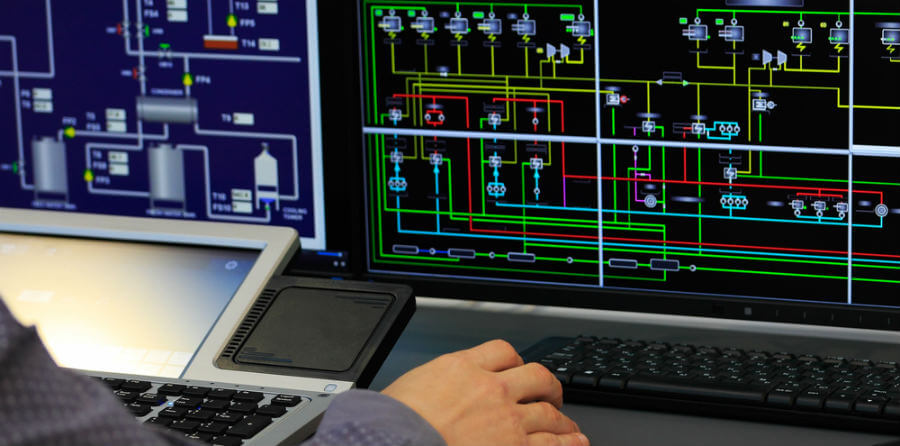

An MES is a digital system that helps with tracking, control, and documentation of your manufacturing processes. It provides insight into how component materials become finished products. By tracking real-time workflow, you can see potential problems and bottlenecks, schedule maintenance around production schedules and orchestrate maximum value.

Why MES?

In a functional sense, MES systems help with several areas that range from process management to job execution.

In an MES production facility, the software may track process definitions through paperless work instruction software, resource scheduling, job execution, data collection and business intelligence for electronics manufacturing, equipment management, quality control, material track and trace, and various reporting tasks.

To best optimize productivity, you need to be able to see the schedule, cost, quality and utilization numbers to understand the total cost of every unit produced.

At Optel, our manufacturing inventory control software helps you streamline production. Find out how you can operate at peak efficiency without overstocking and meet all compliance regulations at the same time.

Upgrading Your Spreadsheets

While many of the processes and reporting included in a manufacturing execution system can be tracked via spreadsheet, the manual entry time drives administrative costs through the roof.

Highly regulated industries, like producing electronic medical devices, require that you document your processes quickly and efficiently. When something goes wrong, authorities need full transparency on your supply chain.

Tracking with spreadsheets has been a method adopted by many manufacturing businesses, but it creates slowdowns when expanding or when information from the plant is needed for enterprise systems. MES management works with existing ERP software to bridge the gap between factory and executive levels.

Creating real-time reports means that management can handle problems as they occur and review issues while production continues, rather than waiting for a shutdown.

Automate Tracking and Production

The benefits of automation are clear, and they don’t end on the production line. Delicate electronic components have specific requirements from temperature controls to static elimination, and meeting these requirements often means continual measurement and tracking.

With MES production in place, that oversight happens automatically. MES component traceability seamlessly integrates with ERP systems, so upper management can make decisions about procurement and inventory management while also controlling process improvement.

Optel’s MES systems provide a range of functionality that includes:

- Dynamic Production Scheduling

- Materials Management

- Component Traceability

- Smart and Mobile Factory Solutions

- Process Traceability

- Quality Management

- Paperless Work

- Business Intelligence

Give your factory the systems it needs to maximize production while minimizing waste with Optel’s MES for electronics manufacturing.

Is MES Right for You?

If you struggle with visibility, time-to-market or compliance issues, MES might be a solution that can help. By obtaining accurate, real-time data, you can solve problems before they snowball. Why do you need an MES? MES systems help you stay innovative, agile, data-driven, transparent, timely and accurate.

Contact Optel today to find out how our systems can help reduce errors, control costs and drive productivity and efficiency up.